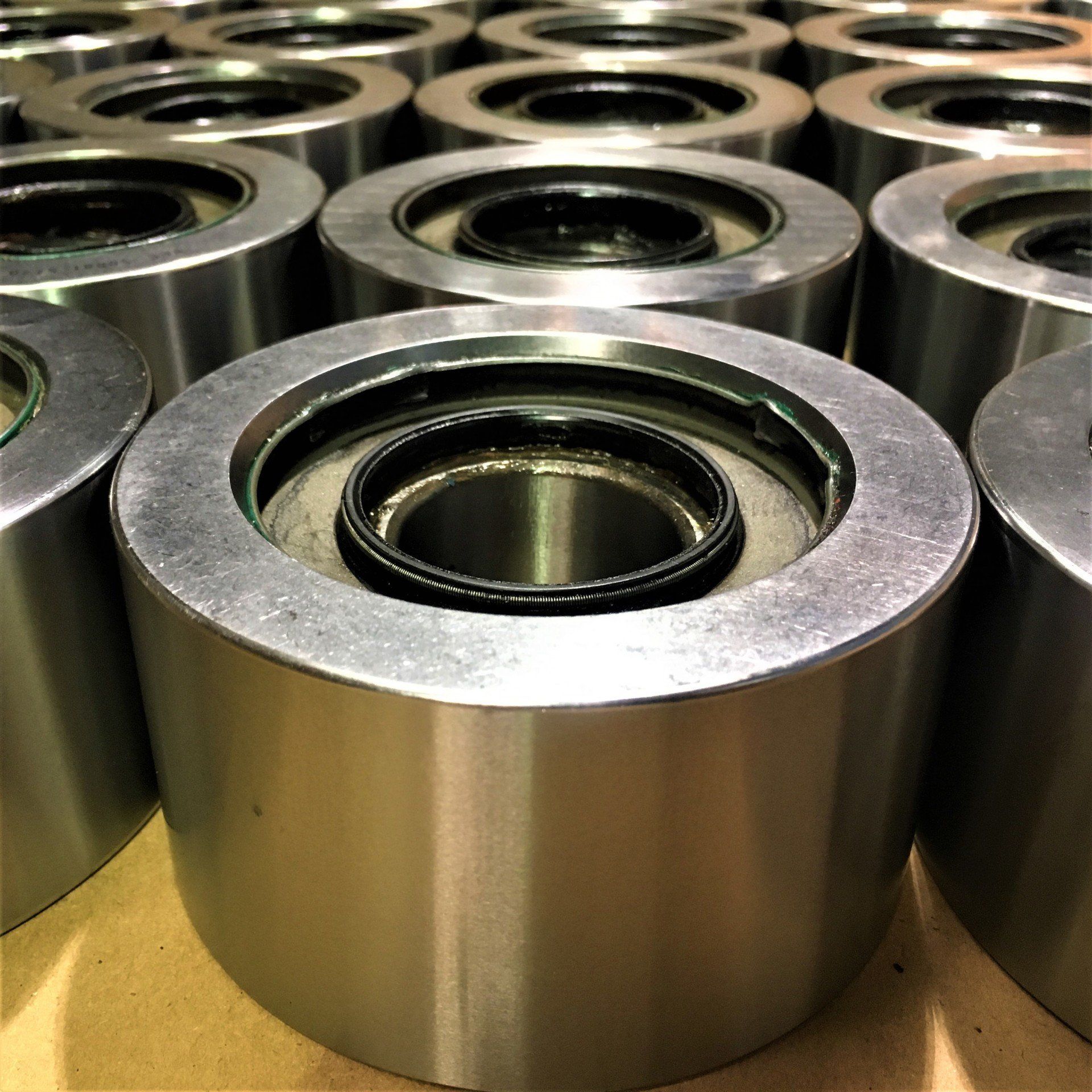

Work Roll / Leveller Roll Repair

RCR Engineering offer a full work roll / leveller roll / pinch roll re-grind and repair service. The need for flawless surfaces and concentricity across rollers is paramount for the quality of the end product; it is this understanding that allows us to offer comprehensive repairs on leveller and pincher rollers, at a fraction of the cost of replacements.

A leveller or pincher roller repair typically involves:

A leveller or pincher roller repair typically involves:

- Inspection of roller, or set of rollers.

- Re-centre to ensure concentricity

- Option 1 - grind rollers to a new standard size

- Option 2 - grind rollers to remove damage and then hard chrome plate to original size

- Rollers are polished to requried standard

- Damaged journals may also be ground and hard chrome plated to original size